Выбор ткани является наиболее важным фактором долговечности и комфорта купальников, особенно для изготовителей купальных костюмов на заказ. Различные ткани влияют на то, как долго длится купальник и насколько хорошо он подходит после многократного использования. Ткань также влияет на то, как она ощущается против вашей кожи. Лабораторные тесты показывают, что смеси нейлона и спандекса хорошо растягиваются, сохраняют форму и кажутся гладкими. Полиэфирно-спандексные смеси отлично отводят влагу и обеспечивают лучшую защиту от солнца.

Если вы хотите пошаговое руководство по выбору подходящей ткани для любого типа купальника, ознакомьтесь с нашей подробной основной статьей: 【Как выбрать ткань для купальников (Полное руководство)】

Смесь ткани (соотношение) | Стрейч (%) | Эластичное восстановление (%) | Отвод влаги (г/м² · ч) | Рейтинг на ощупь (1-10) | УФ стабильность | Долговечность (циклы Мартиндейла) |

|---|---|---|---|---|---|---|

Нейлон 75%/Спандекс 25% | ~ 60 | ~ 92 (после 100 циклов) | ~ 800 | 9 (шелковистый) | Умеренный | ≥ 25 000 (основы-трикотажная вязка) |

Полиэстер 80%/спандекс 20% | ~ 50 | ~ 90 (после 100 циклов) | ~ 1200 | 7 (гладкая) | Высокий | ~ 15 000 (утка-трикотаж) |

Хлопок 60%/Спандекс 40% | ~ 40 | ~ 85 | ~ 400 | 8 (мягкий) | Низкий | Н/А |

Для изготовителя пользовательских купальников выбор правильной ткани имеет решающее значение для производства прочных и стильных купальников. Инновационные ткани, такие какРегенерированный нейлон, Теперь обладают прочностью и растяжением, сопоставимыми с традиционными материалами. Эти достижения помогают купальникам прослужить дольше и обеспечить лучшую посадку. Понимание типов тканей имеет важное значение для изготовителей пользовательских купальников, чтобы сделать осознанный выбор и обеспечить удовлетворенность клиентов.

Ключевые выходы

Выбор правильной ткани помогает купальникам держаться долго и чувствовать себя хорошо. Нейлон и спандекс хорошо растягиваются и кажутся мягкими. Но они не очень хорошо сопротивляются хлору и солнцу. Полиэфирно-спандексные смеси лучше защищают от хлора и ультрафиолетовых лучей. Они сохраняют яркие цвета и делают ткань прочной. Экологичные ткани как ECONYL®И REPREVE®Прочные, как обычные ткани. Они также помогают окружающей среде. С заботой о купальниках,Тестирование качества, А использование хорошей отделки помогает купальникам работать лучше и делать клиентов счастливыми.

Ключевые качества ткани купальников

Источник изображения:Pexels

Растяжка и гибкость

Купальники должны растягиваться и двигаться вместе с вами. Спандекс, также называемый эластаном, Помогает купальникам сильно растягиваться. Волокна спандекса могут стать в шесть раз длиннееА затем вернуться к нормальной жизни. Это позволяет пловцам легко двигаться и сохраняет купальники плотными после многократного использования. Нейлон, смешанный со спандексом, прочный, эластичный и гладкий на ощупь. Ребристые ткани из нейлона и спандексаОказывают дополнительную поддержку активным пловцам. Сочетания полиэстера и спандекса также хорошо растягиваются и помогают купальникам сохранять форму. Эти особенности делают купальники удобными и служат дольше.

Основные особенности растяжения и гибкости:

Высокая эластичность для легкого движения

Сохраняет форму после растяжения

Легкое ощущение с меньшим количеством

Мягкий на коже

Хлор и UV сопротивление

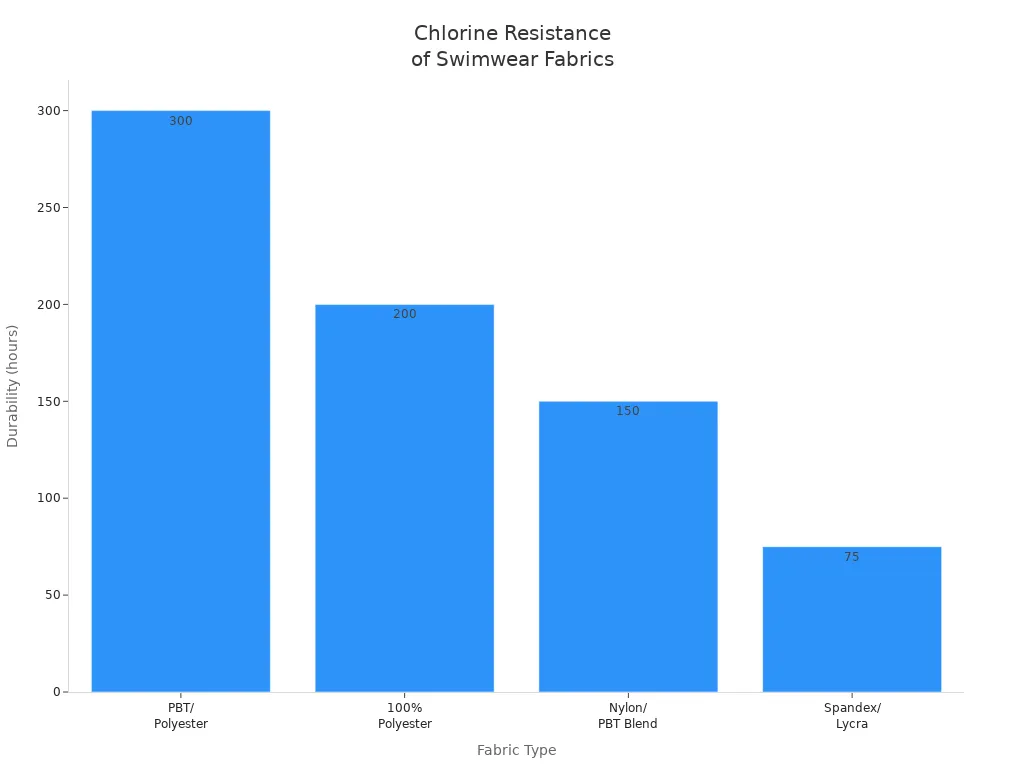

Хлор и солнечный свет могут повредить купальник с течением времени. Полиэстер очень хорош в борьбе с хлором и УФ-лучами.. Купальники из полиэстера дольше других сохраняют свой цвет и прочность. Нейлон на ощупь гладкий и хорошо сидит, но не борется с хлором и полиэстером. Комфортные и прочные смеси спандекса, но только спандекс быстрее распадается в бассейнах. Полиэфирные ткани PBT защищают лучше всегоИ держите купальники новыми после многих плавков.

Параметр теста | Измерение/Результат |

|---|---|

Уменьшение разрывной силы | |

Уменьшение разрывной силы | 65,7% после 300 часов воздействия хлора |

Защита от ультрафиолета (UPF) | 25-39 для тканей с улучшенным ПБТ |

Ранг сопротивления хлора | PBT/полиэстер: отлично (300 + часов) |

100% полиэстер: очень хорошо (200 + часов) | |

Смесь нейлона/PBT: хорошо (150 + часов) | |

Спандекс/лайкра: плохой (50-75 часов) |

Совет: выберите купальники из смеси ПБТ или полиэстера, чтобы они не выцветали и не провисали. Это лучше всего для тех, кто много плавает.

Быстрая сушка и воздухопроницаемость

Быстросохнущие и дышащие ткани делают купальники более удобными и полезными. Микротан®Высыхает в семь раз быстрееЧем обычная ткань. Трансол высыхает в три раза быстрее и позволяет воздуху перемещаться через крошечные отверстия. Пловцы чувствуют себя менее влажными и могут быстро менять деятельность. Дышащие купальники на ощупь легкие и не мнется, поэтому они хороши для путешествий и занятий спортом. Многим нравятся эти особенности и они дают высокие оценки за быстросохнущие и легкие купальники.

Преимущества быстрой сушки и воздухопроницаемости:

Менее ощущение влажности

Меньше раздражения кожи и натирания

Легкий дизайн для легкого перемещения

Высокие рейтинги для активных людей

Купальники производители используют эти функции ткани, чтобы сделать продукты, которые длятся, чувствовать себя хорошо, и хорошо работать во многих местах. Сосредоточив внимание на растяжке, сопротивлении и скорости высыхания, они гарантируют, что купальники соответствуют потребностям каждого.

Типы тканей для купальников

Источник изображения:Pexels

Нейлон-Спандекс Смеси

Нейлон-спандекс смеси являются обычным выбором для купальников. Эти ткани сочетают прочность нейлона с эластичностью спандекса. Нейлон помогает ткани оставаться прочной и прижиматься после растяжения. Спандекс, также называемый лайкрой, позволяет тканиРастягиваться во всех направлениях. Это обеспечивает плотную посадку купальников и сохраняет форму после многих носков. Нейлон-спандекс смеси чувствовать себя мягкой и гладкой на вашей коже. Многим нравится этот комфорт, особенно для стильных купальников или нежных дизайнов. Ткань быстро сохнет, не рвется и не заедает. Но смеси нейлона и спандекса лишь немного защищают от хлора и солнечного света. Со временем цвета могут исчезнуть, а ткань может стать слабее, если много использовать в бассейнах или на солнце. Новые материалы какЭкстра лайкра®Сделать смеси нейлона и спандекса дольше. Эта специальная ткань борется с хлором, жарой и солнечными лучами. Купальники служат намного дольше, чем обычный спандекс. Тем не менее, смесь полиэстера и спандексаСлужат еще дольше и лучше сохраняют свой цвет.

Примечание: смеси нейлона и спандекса лучше всего подходят, когда комфорт и посадка наиболее важны. Изготовители купальников на заказ часто используют эту ткань, потому что она приятна на ощупь и хорошо растягивается.

Имущество | Нейлон-спандекс смесь |

|---|---|

Комфорт | Мягче, гладче, шелковистее, нежнее для кожи |

Стретч & эластичность | Превосходное растяжение, отлично подходит для сжатия |

Управление влаги | Впитывает пот, меньше впитывает влагу |

Скорость сушки | Быстрая сушка |

Долговечность | Умеренная долговечность, устойчив к заеданий и разрывов |

Сопротивление УЛЬТРАФИОЛЕТОВОГО & хлора | Умеренный |

Смеси полиэстер-спандекс

Смеси полиэстера и спандекса теперь являются основным выбором для прочных купальников. Полиэстер хорошо защищает от хлора, соленой воды и солнечного света. Эта тканьСохраняет форму и не тает. Он сохраняет яркие цвета даже после многих стирок и времени на солнце. Полиэстер быстро сохнет и лучше справляется с потом, чем нейлон. Это делает его отличным для активных пловцов. Спандекс в смеси придает ткани эластичность и гибкость. Ткань плотно прилегает, легко перемещается и остается удобной при долгом плавании. Полиэстер-спандекс смеси хороши для печати конструкций, которые длятся. Изготовители купальников на заказ используют эти смеси для ярких, детальных отпечатков. Эти смеси проверяются, чтобы убедиться, что они держатся долго, сохраняют свой цвет и сохраняют свою форму. ОниСоответствуют правилам безопасности и охраны окружающей среды, таким как Oeko-Tex и ISO. Изготовители пользовательских купальников доверяют этим смесей для стабильного качества и хороших результатов.

Полиэстер-спандекс смеси имеют следующие основные преимущества:

Отличная защита от хлора и солнечных лучей

Очень прочный и держит форму

Быстро сохнет и обрабатывает пот

Подходит для тех, кто много плавает

Тип ткани | Удерживание цвета & УЛЬТРАФИОЛЕТОВОЕ сопротивление | Стойкость & простирания | Примечания | |

|---|---|---|---|---|

Полиэстер-спандекс (с PBT) | Высокий | Отлично | Очень прочный, противостоит растяжению | Идеально подходит для соревновательных купальников |

Больше хороших вещей:

Не выцветает и не изнашивается быстро

Спандекс помогает растягиваться и хорошо подходить

Совет: смеси полиэстера и спандексаЛучший для купальниковЭто должно длиться долго, особенно для людей, которые часто плавают или в жесткой воде бассейна.

Устойчивые варианты

Экологичные ткани для купальников становятся все более популярными. ЭКОНИЛ®Регенерированный нейлон и REPREVE®Переработанный полиэстерЭто лучший выбор. Эти ткани используют отходы из океанов, свалок или старых пластиковых бутылок. Это помогает планете, делая меньше мусора. Экологичные ткани такие же прочные, как и обычные. ЭКОНИЛ®Хорошо защищает от хлора и солнечных лучей. РЕПРЕВИТЬ®Хорошо тянется, сохраняет цвет и выдерживает пот. Некоторый переработанный полиэстер может показаться немного менее мягким, чем новый полиэстер, но он по-прежнему удобен и хорошо работает. Полиамиды на растительной основе, такие как EVO от Fulgar®, Мягкие, как хлопок, и получаются из растений.

Тип ткани | Долговечность | Особенности комфорта | Воздействие окружающей среды |

|---|---|---|---|

ЭКОНИЛ®Регенерированный нейлон | Спички или превышает девственный нейлон; превосходный хлор и УЛЬТРАФИОЛЕТОВОЕ сопротивление | Мягкий, высокопроизводительный, бесконечно перерабатываемый | Сделанный из отхода океана и свалки; сохраняет сырую нефть |

РЕПРЕВИТЬ®Переработанный полиэстер | Прочный с влагоотводом и сохранением цвета; немного менее мягкий, чем натуральный полиэстер | Хорошее сопротивление растяжению и выцветанию | Изготовлен из переработанных пластиковых бутылок; более низкий углеродный след |

Полиамиды на растительной основе (например, EVO) | Сопоставимая долговечность; альтернатива без пластика | Мягкое, похожее на хлопок ощущение | Получено из возобновляемых растительных источников; на биологической основе |

Экологичные ткани для купальников помогают брендам заботиться о планете. Изготовители пользовательских купальников используют эти материалы для удовлетворения потребностей клиентов в экологически чистых продуктах. Эти ткани могут стоить дороже и требуют больших заказов, но они помогают брендам выделяться.

Хорошие вещи об экологически чистых тканях купальников:

Очень прочный и защищает от хлора

Удобен и хорошо тянется

Лучше для окружающей среды

Помогает сделать купальники ответственным образом

Примечание: экологически чистые варианты позволяют изготовителям пользовательских купальников предлагать высококачественные зеленые купальники, удобные, прочные и стильные.

Роль спандекса/лайкры в купальники

Спандекс, также называемый лайкрой или эластаном, очень важен в купальниках. Это позволяет ткани растягиваться во всех направлениях. Благодаря этой эластичности купальники плотно прилегают к ним и позволяют легко двигаться. Экстра лайкра®Защищает от солнца и повреждения хлором. Это помогает купальникам сохранять форму и служить дольше. Большинство тканей для купальников имеют около 20% спандекса. Это дает хорошее сочетание растяжения, воздухопроницаемости и прочности.

Спандекс/лайкра помогает купальникам:

Позволять ему растягиваться во всех направлениях

Сохранение формы и формы после многих носков

Делает его более сильным против хлора и солнечного света

Добавление комфорта и легкого движения

Изготовители пользовательских купальников используют смеси спандекса, чтобы сделать купальники, которые хорошо сидят и долговечны. Качественные команды проверяют эти ткани, чтобы убедиться, что они растягиваются, длятся и чувствуют себя хорошо.

Выбор ткани для пользовательских производителей купальников

Тестирование качества и сертификация

Изготовители пользовательских купальников используют строгую проверку качества. Они хотят, чтобы каждый купальник был безопасным и хорошо работал. Каждая ткань проходит испытания на прочность, комфорт и эффективность.. Эти тесты проводятся в специальных лабораториях, а также в реальной жизни. В таблице ниже показаны некоторые тесты и почему они имеют значение:

Аспект теста | Стандарт (ы) | Назначение/Описание |

|---|---|---|

Растяжка и восстановление в 4 направлениях | АСТМ Д3107, ИСО 14704-1 | Измеряет растяжимость ткани и способность возвращаться к исходной форме. |

Stretch & Восстановление | АСТМ Д4964, ЭН 14704-1 | Проверяет эластичность и восстановление после вытягивания. |

Предел прочности | ИСО 2062 | Перед разрушением оценивает прочность и растяжение пряжи. |

Сопротивление хлора | AATCC TM147 | Оценивает стойкость ткани к воздействию хлора. |

Цветостойкость | ИСО 105-К06, ИСО 105-С12, ИСО 105-Э04 | Проверяет сохранение цвета после стирки, трения и потоотделение. |

Сопротивление ссадины | Мартиндейле (ИСО 12947), АСТМ Д4970 | Испытания на устойчивость к катышкам и износу. |

Они также проверяют защиту от ультрафиолета, как быстро ткань высыхает и насколько хорошо она отводит пот. Люди пробуют образцы, чтобы увидеть, хорошо ли они себя чувствуют и работают в воде. Прежде чем делать много купальников, они выбирают ткань, делают образцы, подходят к ним и устраняют любые проблемы. Команды проверяют каждую группу купальников, чтобы убедиться, что они все одинаковые.

Сертификаты очень важны для купальников. Эко-Текс Стандарт 100Является наиболее используемым. Это означает, что ткань не имеет ничего вредного и безопасна для людей. Некоторые производители также получают Oeko-Tex STeP или GOTS для дополнительной безопасности и заботы о планете. Эти сертификаты помогают клиентам доверять бренду и показывают, что компания заботится о безопасности и окружающей среде.

Совет: всегда выбирайте купальники с хорошими сертификатами. Это означает, что ткань безопасна, качественна и сделана правильно.

Отзывы клиентов и использование в реальном мире

Мнения клиентов помогают производителям выбрать лучшие ткани. Они спрашивают людей, что они думают, с помощью опросов, обзоров и форм обратной связи. Это помогает им знать, что людям нравится или не нравится в купальниках. Производители используют эту обратную связь для:

Дайте больше вариантов нестандартных купальников.

Создавайте лучшие проекты из реальных пользовательских идей.

Создавайте доверие, слушая клиентов.

Найдите новые стили или экологически чистые материалы.

Выберите ткани, которые длятся, чувствовать себя хорошо, и зеленый.

Продолжайте совершенствовать купальники и следите за новыми тенденциями.

Производители также смотрят на то, как ткани работают в реальной жизни. Они измеряют растяжение, восстановление, устойчивость к хлору и ультрафиолетовому излучению, износ морской воды, контроль пота, время сушки, воздухопроницаемость, сжатие и стойкость цвета. В таблице ниже показаны важные цифры:

Аспект производительности | Метрики/Значения | Цель/Воздействие |

|---|---|---|

Ткань стрейч | 30-60% удлинение при разрыве | Обеспечивает посадку по фигуре и свободу движений |

Эластичное восстановление | > 90% восстановление после 50 циклов при 15% деформации | Сохраняет компрессию и предотвращает провисание |

Сопротивление хлора | > 90% удержание при растяжении после 100 ч в 10 ppm хлора | Обеспечивает долговечность в бассейнов |

Устойчивость к ультрафиолетовому излучению | Удерживание прочности 75-90% на дозе ² 100-200 кДж/м УЛЬТРАФИОЛЕТОВОЙ | Защищает целостность волокна и стабильность цвета |

Ссадины соленой воды | 3-10% увеличение истирания после 10-50 солевых циклов | Измеряет износ ткани от воздействия соли |

Скорость отвода влаги | 0,8-1,2 см/с (гидрофильная отделка) | Втягивает воду с кожи для комфорта |

Время высыхания | 5-8 минут (с гидрофильной отделкой) | Ускоряет испарение и уменьшает озноб |

Воздухопроницаемость (МВТР) | > 8 000 г/м² · 24 ч | Обеспечивает циркуляцию воздуха, снижает сырость |

Уровни сжатия | 10-20 мм рт. ст. | Стабилизация мышц и снижение сопротивления (до 7%) |

Вес ткани | 140-250 GSM | Уравновешивает сжатие, растяжение и долговечность |

Цветовая стойкость | Протестировано через лабораторные протоколы | Обеспечивает сохранение цвета после выдержки и стирки |

Стойкость финиша | 20-40 циклов стирки для гидрофильной и DWR отделки | Указывает на долговечность обработки ткани |

Некоторые бренды используютУмные купальники с датчиками. Эти датчики отслеживают такие вещи, как частота сердечных сокращений и скорость плавания. Это помогает производителям увидеть, как работает ткань, когда люди плавают.

Производители часто меняют свой выбор тканей, иногда каждый сезон. Это помогает купальникам оставаться новыми, удобными и хорошо работать.

Обрезки и дополнительные материалы

Хорошая отделка и дополнительные материалы имеют не меньше значения, чем основная ткань. Отделка-это такие вещи, как резинки, подкладки, молнии, крючки и украшения. Они должны быть прочными и не разрушаться в хлоре, соленой воде или солнечном свете.

Нержавеющая фурнитура и мягкая подкладка делают купальники лучше.

Экологичные отделки вродеЭКОНИЛ®И сильный эластанБороться с хлором, солнцезащитными кремами и маслами.

УФ-защитные нарезки помогают купальникам держаться и защищать кожу.

Тщательная работа и местное изготовление помогают контролировать качество.

Сильная отделка означает меньше ремонтов и счастливых клиентов.

Примечание. Выбор хорошей отделки и материалов предотвращает такие проблемы, как свободные стежки, слабые швы или плохое прилегание.

Влияние качества ткани на окончательный продукт купальников

Качество ткани меняет то, как работают купальники и насколько довольны клиенты. Хорошие материалы хорошо растягиваются, быстро сохнут, борются с хлором и солнцем. Использование одного и того же материала каждый раз означает, что купальники соответствуют образцам и имеют меньше ошибок. Тестирование цвета сохраняет купальники новыми, что делает клиентов счастливыми.

Тщательная проверка во время изготовления, например, осмотр ткани и тестирование, сохраняет доброе имя бренда. Лучшие материалы, такие как лайкра и спандексДлятся долго, приятно себя чувствовать и хорошо работать. Получение ткани от проверенных поставщиков с сертификатами означает, что купальники безопасны и качественны.

Распространенные ошибки-не проверка растяжки с использованием небольшого количеством эластана., Или сбор натуральных волокон, впитывающих воду. Эти ошибки могут заставить купальники провисать, чувствовать себя плохо и не долго. Производители проверяют каждую ткань и работают с хорошими мельницами, чтобы избежать этих проблем.

Изготовители пользовательских купальников часто добавляют новые технологии и экологически чистые варианты к своим тканям. Это сохраняет их купальники свежими и помогает им конкурировать.

Выбор правильной ткани очень важен для купальников. Ткань влияет на то, как долго длится купальник и как он себя чувствует. Купальники работают по-разному из-заИз чего он сделан, сколько воды он принимает, и как выглядит снаружи. Некоторые специальные купальники, напримерКостюмы для всего тела и компрессионные ткани, Помогите пловцам идти быстрее. Они делают это, делая меньше сопротивления и помогая мышцам работать лучше. Производители, которые заботятся о качестве и тестируют свою продукциюСделать купальники лучше. Они также прислушиваются к тому, что хотят клиенты. Бренды продолжают делать купальники лучше, пробуя новые материалы и запрашивая отзывы. Лучшие бренды купальников остаются популярными, используя новые идеи, заботясь о планете и делая высококачественные продукты.

Бренды купальников, которые заботятся о качестве и следуют новым стилям, возвращают своих клиентов.

Насколько хорошо работает купальник, зависит от ткани, качества и новых идей.

Изготовители пользовательских купальников всегда должны тестировать, слушать и делать вещи лучше.

Часто задаваемые вопросы

Какая ткань держится дольше всего в купальниках?

Полиэстер-спандекс смесиСамые прочные для купальников. Эти ткани не легко повреждаются хлором или солнечным светом. Нейлоновые смеси не служат так долго, как смеси полиэстера. Большинство конкурентоспособных брендов купальников используют полиэстер, потому что он прочный и сохраняет свой цвет.

Совет: выбирайте купальники из полиэстера, если вы много плаваете в бассейнах.

Как спандекс улучшает комфорт купальников?

Спандекс помогает купальникам растягиваться и двигаться вместе с вами. Купальники из спандекса плотно прилегают и двигают, когда вы это делаете. Это волокно сохраняет форму и перестает провисать после многократного ношения.

Спандекс дает следующие преимущества:

Лучшее движение

Остается на месте

Ощущение мягким

Являются ли экологически чистые ткани купальников прочными, как традиционные?

Экологичные ткани как ECONYL®И REPREVE®Такие же прочные, как обычный нейлон и полиэстер. Эти переработанные ткани не разрушаются от хлора или солнечного света. Они хорошо работают для людей, которые много плавают.

Тип ткани | Долговечность | Воздействие Эко |

|---|---|---|

ЭКОНИЛ® | Высокий | Отлично |

РЕПРЕВИТЬ® | Высокий | Отлично |

Как нужно заботиться о купальниках, чтобы продлить им жизнь?

После использования промойте купальник холодной водой. Не перекручивайте и не кладите его в сушилку. Положите его высохнуть вдали от солнца. Эти шаги помогают сохранить растяжку и цвет.

Примечание: уход за купальником предотвращает выцветание и повреждение.